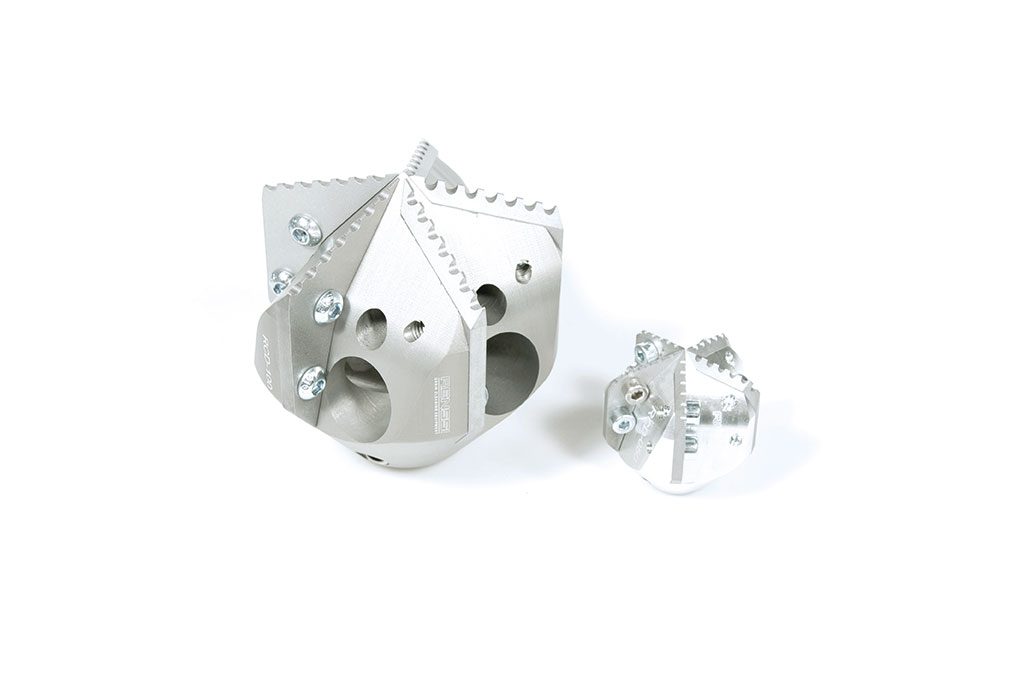

Chain knockers

There are chains for all areas of application and all common pipe cleaning machines. We sell chains with and without carbide attachments as well as disc chains with carbide attachments or only carbide coated. They fit on the RENSSI system, on T-slot connections in 16, 20 and 22 mm as well as on square clutches.

Ask for the prices! A comparison could be worth it!

All products in this category can also be ordered directly in our store under “Chain Knockers“.

Cutting tools

The cutting tools are used in various areas of the inliner process. They can be used, for example, to open up glued-up inlets or remove collapsed liners. In addition, the “excess cutter” can be used to cut off a closed end.

All products in this category can also be ordered directly in our store under “Cutting tools“.

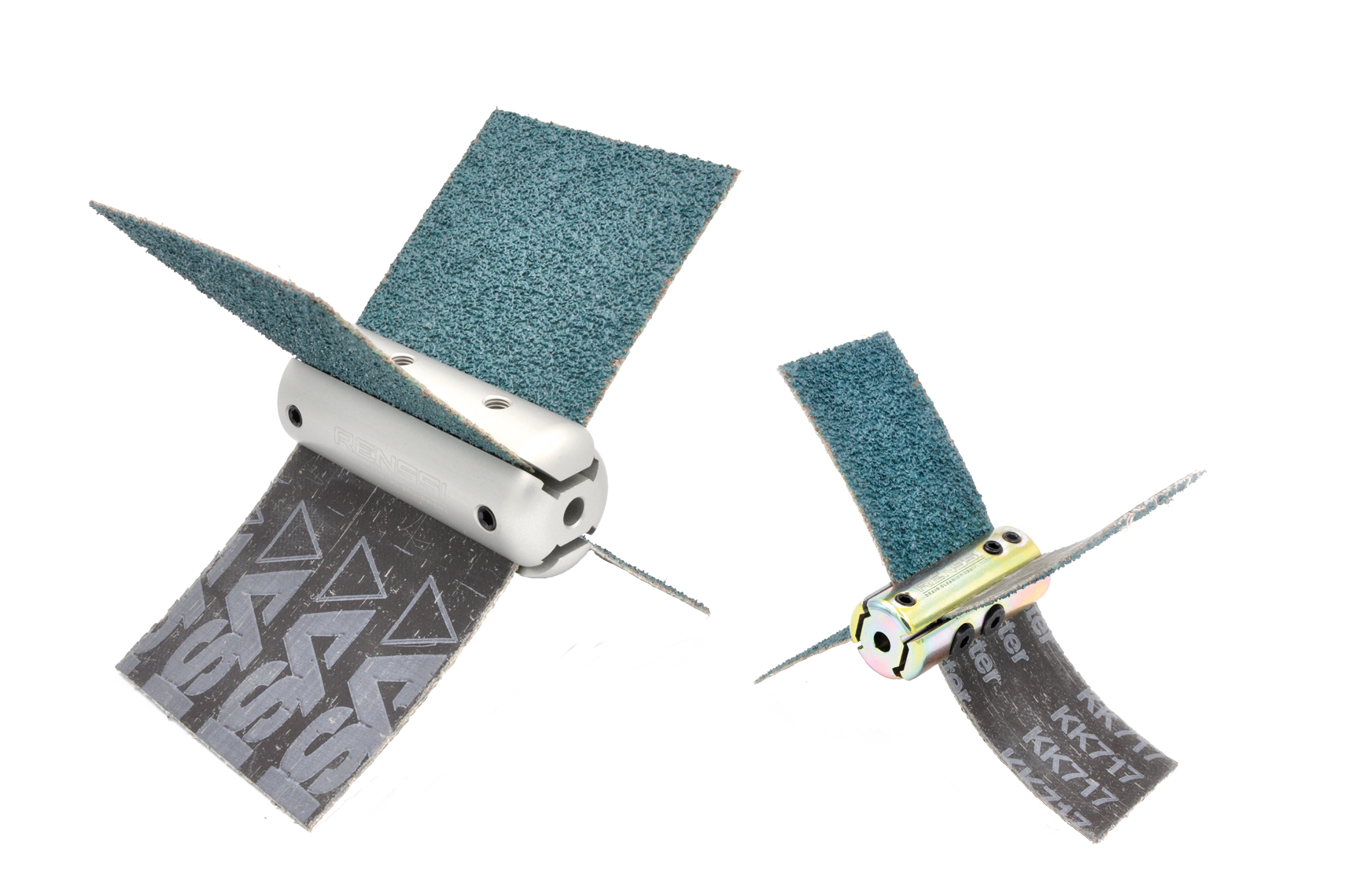

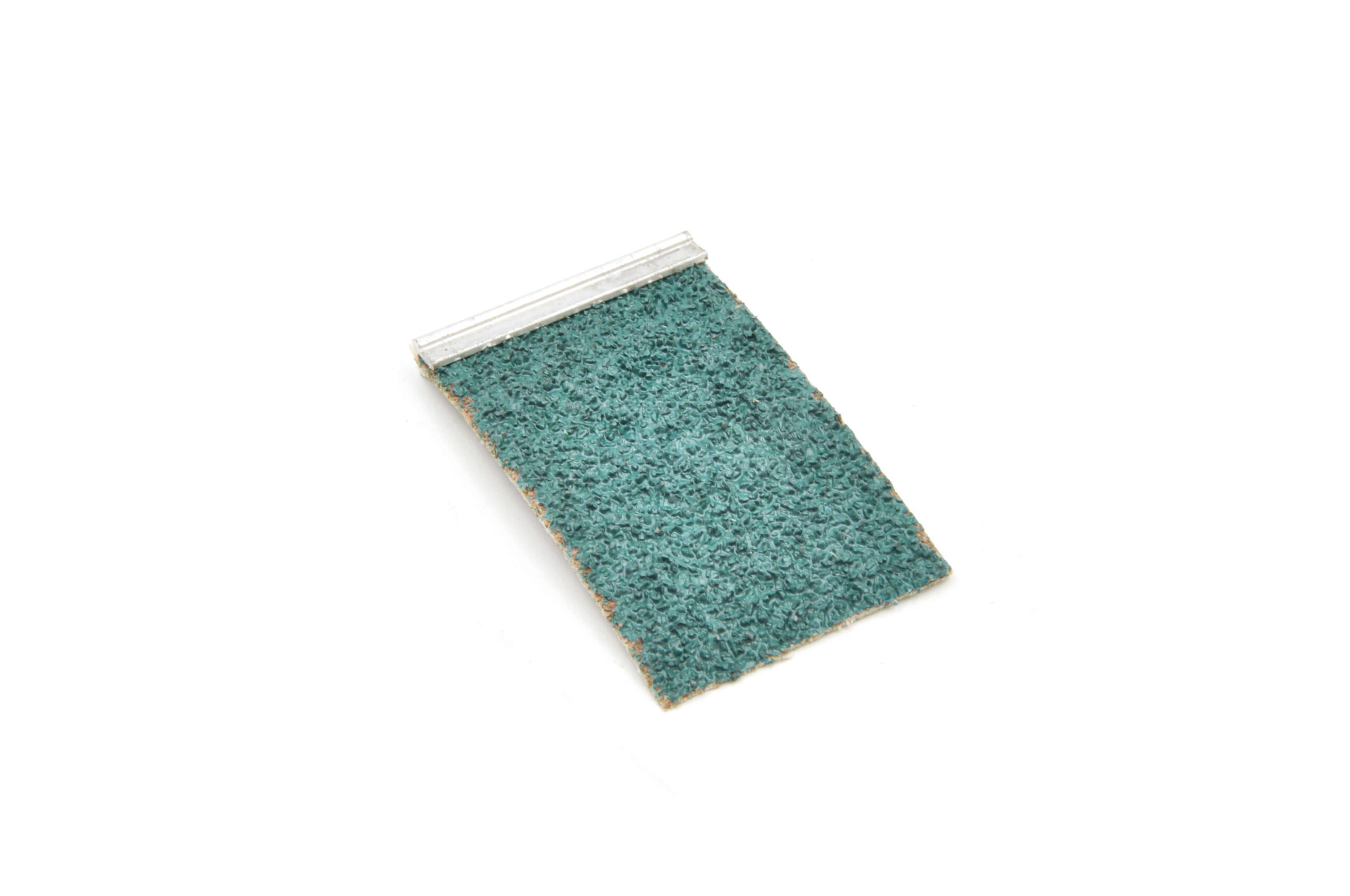

Sandpaper

Four sandpapers are attached to the sandpaper holder in order to rotate them in an opened inlet. With the help of the sandpaper, the ” roughly ” opened inlet is grinded out cleanly. There are two different sizes for different pipe diameters.

All products in this category can also be ordered directly in our store under “Sandpaper“.

Nylon / Steel brushes

Brushes are perfect for cleaning plastic pipes without damaging them. They can also be used to center various tools. They are especially suitable for cleaning before spraylining. The brushes are made of high quality nylon or steel and both in combination. They are available from DN 50 to DN 200, and with a purchase quantity of 10 pieces, we can also create individual brushes according to your needs.

All products in this category can also be ordered directly in our store under “Brushes“.

Cable Carrier

The handy, cost-effective and professional solution to store the cable spiral cleanly before, during and after use.

The Cable Carrier is available in four different versions: With 10 mm, 8 mm or 6 mm cable spiral or completely without, to use it together with your already existing cable spiral.

All products in this category can also be ordered directly in our store under “Cable Carrier“.